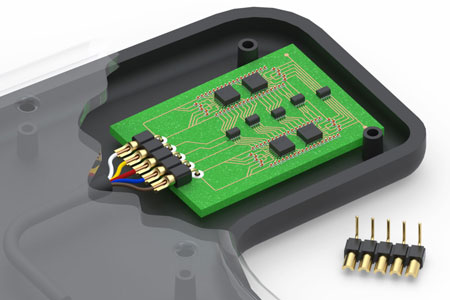

Streamline wire to board connections by reducing wire handling

New 380-10-1XX-10-003000 series right-angle headers are ideal for situations where space is limited and wires cannot be easily manipulated. These solder cup headers expedite the soldering process and reduce overall assembly height by eliminating the need to bend wires or cables for in-line connections. Designed to simplify wire to board terminations, the solder cups are uniformly aligned to facilitate efficient soldering, especially useful for terminating cables, and can accept up to 22 AWG stranded wire. Rotation limiting features built into the insulator and pins keep solder cups and right-angle tails in place during soldering and termination processes.

These are single row connectors with .100” (2,54 mm) pin spacing and .020” (,51 mm) diameter tails suitable for mating with a variety of sockets or terminating directly to a P.C.B. They deliver an above-board profile of .100” (2,54 mm) when soldered directly to the circuit board and when mated with Mill-Max low profile board mounted sockets 315-XX-1XX-41-003000 a total interconnect height of .175” (4,45 mm) is achieved. They can also mate with Mill-Max standard solder cup sockets 329-XX-1XX-41-540000 for use in wire termination applications such as cable assemblies. The insulator material is high-temperature PCT polyester with an HDT of 230° C to withstand most soldering processes.

Attachments: